I believe silicon will play a big role in the battery development industry. Several companies are currently working on silicon anode materials, each with their own unique approach to the technology.

Looking Forward at the Future of EV Battery Development

Looking Forward at the Future of EV Battery Development

Q&A with Dr. Michelle Tokarz, VP of Partnerships & Innovation | The Coretec Group

What inspired you to pursue a career in engineering silicon for cleantech and emerging technology markets?

New technologies with market potential have always intrigued me. My doctorate degree in Materials Sciences gives me a strong foundation in basic battery science, and my extensive years of experience in tech-related startups also make me a suitable candidate for this endeavor.

Can you briefly explain the Coretec Group’s Endurion Program?

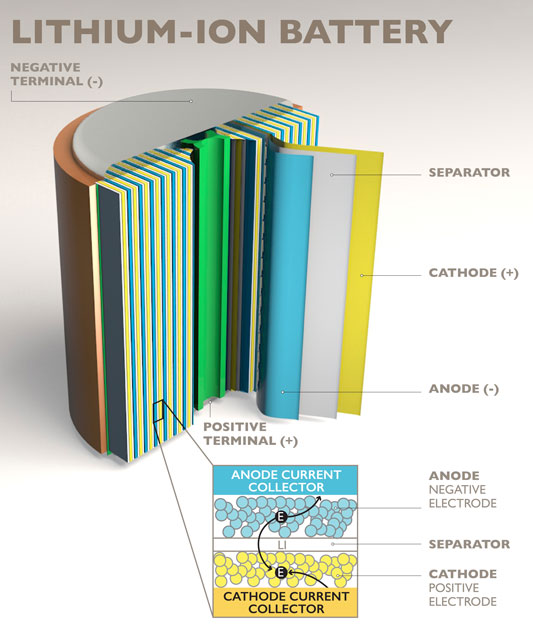

In our Endurion Program, we are modifying very small silicon particles, or nanoparticles, using basic chemistry techniques to attach a polymer-based layer that we are calling our “engineered solid-electrolyte-interphase" or SEI layer. This particular polymer conducts lithium-ions from the electrolyte to the silicon particle at its core. Our one-of-a-kind approach and chemistry set us apart from the rest of the industry. Through the development of our proprietary engineered SEI layer, we are proactively shaping the composition of the SEI layer to optimize battery capacity and cycle life.

What are the key advantages of silicon-based anodes for lithium-ion batteries?

Silicon has a theoretical charge capacity that is 10 times that of graphite, which is the traditional material used for the anodes in lithium-ion batteries. If some of the technical issues, such as the SEI layer, can be addressed, lithium-ion batteries with greater capacity can be realized. Another way to look at this is that the amount of lithium-ions that can be “held” in the anode can be substantially increased. This is directly related to the range. The greater the capacity, the longer the EV battery's range.

What are some of the biggest disadvantages of graphite-based anodes?

Even though graphite is relatively abundant and cheap, it doesn’t have a great charge capacity. When graphite is visualized as sheets of 6-membered carbon rings, every lithium-ion that enters the graphite anode will situate itself in the center of that 6-member ring. This means that every six carbon atoms will attach to one silicon atom. This results in significantly reduced battery capacity. With range anxiety continuing to be a major concern, to fully support electrification, we need to build EVs that the average consumer will find attractive and that meets their driving needs. Given the inherent charge capacity of graphite, it is highly unlikely that 100% graphite anodes will continue to be the standard in lithium-ion batteries.

How do you see the battery development industry evolving in the next few years?

In the next few years, I believe silicon will play a big role in the battery development industry. Several companies are currently working on silicon anode materials, each with their own unique approach to the technology. It makes sense to continue to perfect these tweaks to get the most out of the silicon in our anodes. The United States is “late to the game” in battery development, falling far behind China and Europe. It will be intriguing to observe the impact of government incentives on the broader global ecosystem.

What are the biggest challenges Coretec must overcome in trying to develop an EV battery that will be adopted as the new industry standard?

At the Cortec Group, our Endurion program has made strong advancements proving that our silicon anode works. Building on these successes, our next challenge is to optimize the silicon load while keeping an eye on the manufacturing scalability. Our recent provisional patent identifies three separate processes for possible production at scale. We are confident that our knowledgeable team of experts, coupled with our partnerships with the University of Michigan Battery Lab, Polaris Battery Lab, and Wayne State University, will rise to the challenge and drive our desired results for Endurion.

At the Cortec Group, our Endurion program has made strong advancements proving that our silicon anode works. Building on these successes, our next challenge is to optimize the silicon load while keeping an eye on the manufacturing scalability. Our recent provisional patent identifies three separate processes for possible production at scale. We are confident that our knowledgeable team of experts, coupled with our partnerships with the University of Michigan Battery Lab, Polaris Battery Lab, and Wayne State University, will rise to the challenge and drive our desired results for Endurion.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product