The Future of Warehouse Sustainability

The traditional warehouse has evolved over the years. Sustainability has swooped in and is now a central focus for industries of all kinds. As gradual change comes about, like the switch to renewable energy, warehouse sustainability improves. However, the road ahead requires more changes to improve energy and resource consumption in cleaner ways.

While renewable energy is one of the most vital steps that warehouses must take for the future, the supply chain can improve in subtler ways that add up as well. The key areas to focus on are technology, the environment and public health. Then, warehouses can become sustainable in every sense of the word.

Goals to Work Toward for Warehouse Sustainability

In 2018, the Environmental Protection Agency (EPA) reported that industries accounted for 22% of all greenhouse gas emissions in the United States. This percentage is only second to transportation, which warehouses and supply chains no doubt play a role in, too. This kind of harm is what the future of warehouse sustainability must work to stop.

One way to do so is by identifying the right goals to work toward. The Leadership in Energy and Environmental Design (LEED) certification is one of the most important achievements for the supply chain. It verifies that a third-party has audited a warehouse and ensured it is up to the latest environmental standards.

The LEED certification focuses on reducing energy use, conserving water and lowering the carbon emissions a warehouse produces. A step forward to adhere to these guidelines could be automated assembly lines with robotic arms to consume energy more wisely. Another way forward will involve ensuring the building itself isn’t harming local ecosystems.

Obtaining LEED certification will take a collective effort across the supply chain. For warehouses, the focus becomes utilities, renewable energy solutions and sensors for improving efficiency. Turning these concepts into actions is what warehouses must do to achieve a cleaner future.

The Role of Utilities and Equipment

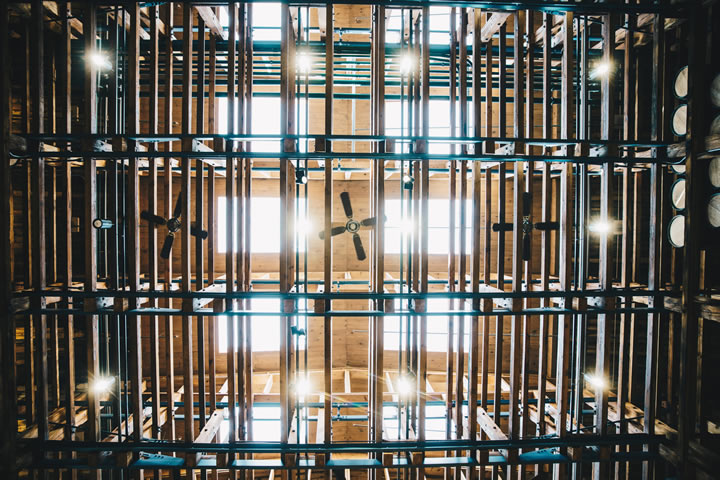

Utilities are a key way for warehouses to become more environmentally friendly. Though these are subtle and sometimes easy to overlook, their energy consumption rates and costs add up quickly. For instance, on average, it costs $2.10 per square foot to pay for utilities in commercial buildings. Lighting almost always makes up most of the utility expenses.

To bring prices down while being sustainable, warehouses can switch to LED bulbs. These bulbs, in comparison to incandescents, conserve about 75% more energy and last around 25 times longer. They can save even more with motion-detecting, automatic shut-off abilities.

Similarly, warehouse equipment can be wasteful and harmful. While more eco-friendly, battery-powered alternatives may eventually come along, managers can take a more immediate path. Using Internet of Things (IoT) sensors on equipment can track their performance and facilitate predictive maintenance. If a machine is underperforming according to the data collected, it may be time for repairs.

Fixing a machine is cheaper than replacing it. However, it’s also more sustainable. E-waste originates from any form of technology and electronic equipment. Some machinery contains harmful materials, like lead, that seep into ecosystems or water supplies when tossed away. This waste adds up, but warehouse employees can curb it proactively.

Instead of throwing away parts, employees can focus on extracting these valuable materials and recycling them. Each contribution adds up and speaks to the idea of a circular economy — where theoretically nothing goes to waste, and every component continues to cycle back around into use.

Sweeping Changes Within Renewable Energy

While warehouse sustainability will see many smaller improvements, the main change must include renewable energy. Luckily, that change is already underway. PVH Europe’s warehouse, for instance, is home to the world’s most powerful solar panel roofing setup. It hosts 48,000 photovoltaic (PV) panels, creating the optimal renewable setup.

Renewable energy has the power to drastically reduce carbon emissions for any warehouse. The key is switching to this electricity source on a larger scale. For the future, it’s now likely that more warehouses will start transitioning as the costs of renewable energy sources like solar and wind continue to drop.

The supply chain, as a whole, must adapt to big changes as well. Warehouses are one stop on the chain, but transportation, for instance, must also become more sustainable. Trucks and shipping processes are big sources of carbon emissions. Transitioning to electric vehicles or less harmful power sources than fossil fuels is the next step for sustainability.

The challenges ahead lie in the biggest changes. However, with a foundation of smaller adjustments, warehouse workers and employees along the supply chain can work toward a more sustainable future.

Circular and Sustainable Warehousing

Creating warehouse sustainability brings about greater public health initiatives and lower costs for the supply chain. Cleaner air from renewable energy will accompany the utility and recycling changes that warehouses make. These steps create a circular system — they reduce waste in any form and show the direction the supply chain is working toward.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product